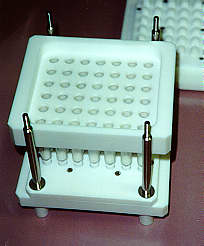

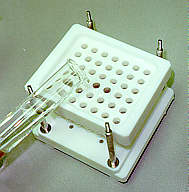

Place the MULTIBLOCK on the lower multistopper and squeeze it until the

individual stoppers are flush with the surface of the plate. Release the

pressure and inspect the fit of all stoppers.

Place the MULTIBLOCK on the lower multistopper and squeeze it until the

individual stoppers are flush with the surface of the plate. Release the

pressure and inspect the fit of all stoppers.

|

| Fill the MULTIBLOCK reactors with the appropriate resin (10-200 mg). Filling can be performed by pouring in the resin suspension and distributing it into the reactors as in the case of a randomization step of library synthesis (see below). In this case, of course, you will end up with the equal amount of a resin in each reactor. You don't have to use all reactors, you can block some reactors by stoppering them by stoppers cut from the Eppendorf tubes (use only tubes made from colored polyethylene -- clear Eppendorf tubes have a slightly bigger diameter and the stoppers don't fit). Never use force to push the stoppers in. You would damage the upper lip of the well. |

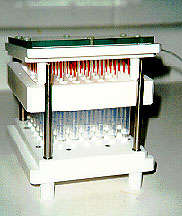

After filling all reactors with the solvent, attach the upper

multistopper and let the resin swell (the whole assembly can be placed

on the shaker or it can occasionally be shaken by hand).

After filling all reactors with the solvent, attach the upper

multistopper and let the resin swell (the whole assembly can be placed

on the shaker or it can occasionally be shaken by hand).

|

Unscrew the holding nuts and pull up the MULTIBLOCK from the lower

multistopper and transfer it to the vacuum adaptor. During this

operation press the upper multistopper against the body of the block so

that the liquid does not leak from the reactors.

Unscrew the holding nuts and pull up the MULTIBLOCK from the lower

multistopper and transfer it to the vacuum adaptor. During this

operation press the upper multistopper against the body of the block so

that the liquid does not leak from the reactors.

|

| Remove the upper multistopper. |

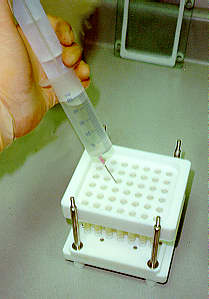

Apply a vacuum to the vacuum adaptor. - Wash the reactors. You can either fill

the reactors using a strong stream (to stir the resin) of the solvent and apply a vacuum after all

reactors are filled, or wash the resin by continuous flow (vacuum is on during liquid addition).

The second option should be avoided in the case of air sensitive preparations. To save the

washing liquid, you can add it by syringe. When you are filling reactors in MULTIBLOCK

without suction, the end of the tubing must be higher than the liquid level in the reactors, or else

the liquid will leak.

Apply a vacuum to the vacuum adaptor. - Wash the reactors. You can either fill

the reactors using a strong stream (to stir the resin) of the solvent and apply a vacuum after all

reactors are filled, or wash the resin by continuous flow (vacuum is on during liquid addition).

The second option should be avoided in the case of air sensitive preparations. To save the

washing liquid, you can add it by syringe. When you are filling reactors in MULTIBLOCK

without suction, the end of the tubing must be higher than the liquid level in the reactors, or else

the liquid will leak.

| |

|

|

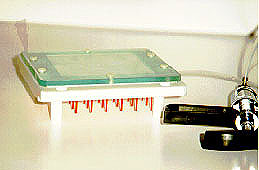

A convenient way of washing is the use of a washing attachment connected to the

Wheaton self-refilling repetitive syringe. The washing attachment can be used

also for simultaneous addition of reagents to all reactors. In this case, any

syringe with a luer-lock can be used. (The luer-lock is important -- to achieve

uniform distribution of the liquid into all vessels, the delivery must be

performed rapidly, thus generating pressure in the tubing connecting the syringe

and the washing attachment. An accidental detachment of the syringe from the

tubing would result in liquid being sprayed all over the place.) Manual

operation of the repetitive syringe can be replaced by the automated actuation

of Cavro, Hamilton, or Kloehn syringe pump driven from the computer. Figures

depict the washing attachment itself and the washing attachment on

top of the MULTIBLOCK attached to the vacuum adaptor. Again, the washing can be

performed either discontinuously (adding the liquid, waiting, suction), or

continuously (adding the liquid with applied vacuum).

A convenient way of washing is the use of a washing attachment connected to the

Wheaton self-refilling repetitive syringe. The washing attachment can be used

also for simultaneous addition of reagents to all reactors. In this case, any

syringe with a luer-lock can be used. (The luer-lock is important -- to achieve

uniform distribution of the liquid into all vessels, the delivery must be

performed rapidly, thus generating pressure in the tubing connecting the syringe

and the washing attachment. An accidental detachment of the syringe from the

tubing would result in liquid being sprayed all over the place.) Manual

operation of the repetitive syringe can be replaced by the automated actuation

of Cavro, Hamilton, or Kloehn syringe pump driven from the computer. Figures

depict the washing attachment itself and the washing attachment on

top of the MULTIBLOCK attached to the vacuum adaptor. Again, the washing can be

performed either discontinuously (adding the liquid, waiting, suction), or

continuously (adding the liquid with applied vacuum).

|

| Remove all liquid from the reactors by suction. |

Wipe the droplets of liquid from the upper surface of the MULTIBLOCK

(e.g. by paper tissue).

Wipe the droplets of liquid from the upper surface of the MULTIBLOCK

(e.g. by paper tissue).

|

| Transfer the MULTIBLOCK to the lower multistopper and make sure that it fits tightly (see above). |

Add the appropriate reagent.

Add the appropriate reagent.

|

Close the block by upper multistopper. Tighten the nuts uniformly on all sides. Do

not overtighten. The best way to find out how much you have to tighten is to close the block

before synthesis with various solvents and find out how tightly you have to close it. Different

solvents need different force. (TFA is the most difficult to hold.)

Close the block by upper multistopper. Tighten the nuts uniformly on all sides. Do

not overtighten. The best way to find out how much you have to tighten is to close the block

before synthesis with various solvents and find out how tightly you have to close it. Different

solvents need different force. (TFA is the most difficult to hold.)

|

Place the MULTIBLOCK on a shaker. Reactors should be shaken horizontally in

the direction of their axes. Shaking reactors in a vertical position makes sense only when working

with small amounts of a resin (20-30 mg). Always make sure that the reactors are not leaking.

Place the MULTIBLOCK on a shaker. Reactors should be shaken horizontally in

the direction of their axes. Shaking reactors in a vertical position makes sense only when working

with small amounts of a resin (20-30 mg). Always make sure that the reactors are not leaking.

|

| After the reaction is completed, transfer the block to the washing station (see above), wash the reactors, and prepare the block for individual couplings. |

Prepare the individual reagents in an array of Eppendorf tubes.

Prepare the individual reagents in an array of Eppendorf tubes.

|

Transfer the solutions to the appropriate reactors using some form of positive

control (marking the reactors to which reagents were already added, puncturing

paper overlayered on top of the wells, etc.). Manual reagent

distribution can be eliminated by integration of MULTIBLOCK with liquid

distribution stations (Packard Canberra, Rosys, Zinsser, Tecan,.....), creating

thus semiautomatic organic synthesizer.

Transfer the solutions to the appropriate reactors using some form of positive

control (marking the reactors to which reagents were already added, puncturing

paper overlayered on top of the wells, etc.). Manual reagent

distribution can be eliminated by integration of MULTIBLOCK with liquid

distribution stations (Packard Canberra, Rosys, Zinsser, Tecan,.....), creating

thus semiautomatic organic synthesizer.

|

Always wash carefully both multistoppers. Poor washing results in

possible contamination and/or leakage of vessels.

|

Add solvent until all reactors are filled, and solvent overfows the

surface of the block slightly. Less solvent will result in nonuniform

bead distribution. More solvent will prevent complete randomization.

Add solvent until all reactors are filled, and solvent overfows the

surface of the block slightly. Less solvent will result in nonuniform

bead distribution. More solvent will prevent complete randomization.

Tightly close the block with the glass cover.

Tightly close the block with the glass cover.

Turn the block upside down and shake it until all reactors are empty.

Turn the block upside down and shake it until all reactors are empty.

Turn the block quickly to the normal position and continue rotating it

for about 10 seconds.

Turn the block quickly to the normal position and continue rotating it

for about 10 seconds.

Inspect for uniformity of distribution. If the distribution was not

successful, repeat the whole process.

Inspect for uniformity of distribution. If the distribution was not

successful, repeat the whole process.